If you’re anything like me, working on your bike is half the fun of owning it. Sure, you can have a bike shop do maintenance for you, and if it’s a big job requiring specialty tools, this might be a good idea. For me, I want to know every part of my bike inside and out, know what makes it go, and know how to take it apart and put it back together. I’m working on overhauling my commuter bike, a Montague Boston, and making it truly custom with all new components. Last time, I stripped most of the old parts that had been beat up from 2 years of all weather commuting. I pulled the crankset, removed the bottom bracket and old brakes, and gave the frame a thorough cleaning.

Now it’s time to take a look at the headset, the set of bearings that allow the front fork to rotate freely in the frame. There are essentially two types of bicycle headsets; threaded, and threadless. A threaded headset, surprisingly, uses a fork with a threaded steerer tube. The top of the headset is a large lock nut which threads onto the fork, and when tightened, sets the compression on the bearings. The headset on my Boston is threadless. The stem clamps directly around the steerer tube and is simply pushed down against the headset bearings to provide compression. This is a more recent design and has become very popular on modern road and mountain bikes. It’s simpler, easier to install and maintain, and doesn’t require anything more than an allen key to take apart.

Start by removing the top cap. This bolt threads into a star nut which is wedged inside the steerer tube. When tightened, it pushes the stem down against the headset to compress the bearings:

In order to get at the headset bearings, you’ll need to remove the stem completely. Simply loosen the two bolts that clamp it to the fork, and slide it up and off:

At this point, the fork will be free to slide down and out of the frame. Part of the headset is a circular wedge, or compression ring, that fits snugly around the top of the steerer tube. Sometimes it does it’s job a bit too well and the fork gets stuck in the frame. If this is the case, just give the top of the steerer tube a tap with a rubber mallet:

As you remove the fork, you’ll see there are several parts to the headset, both above and below the frame’s head tube. As you take them off, try to keep them in order to make re-installation easier. The headset also includes the cups that are press fit into the frame, and the crown race which is pressed onto the base of the fork’s steerer tube. We’ll leave those in place and give everything a thorough cleaning:

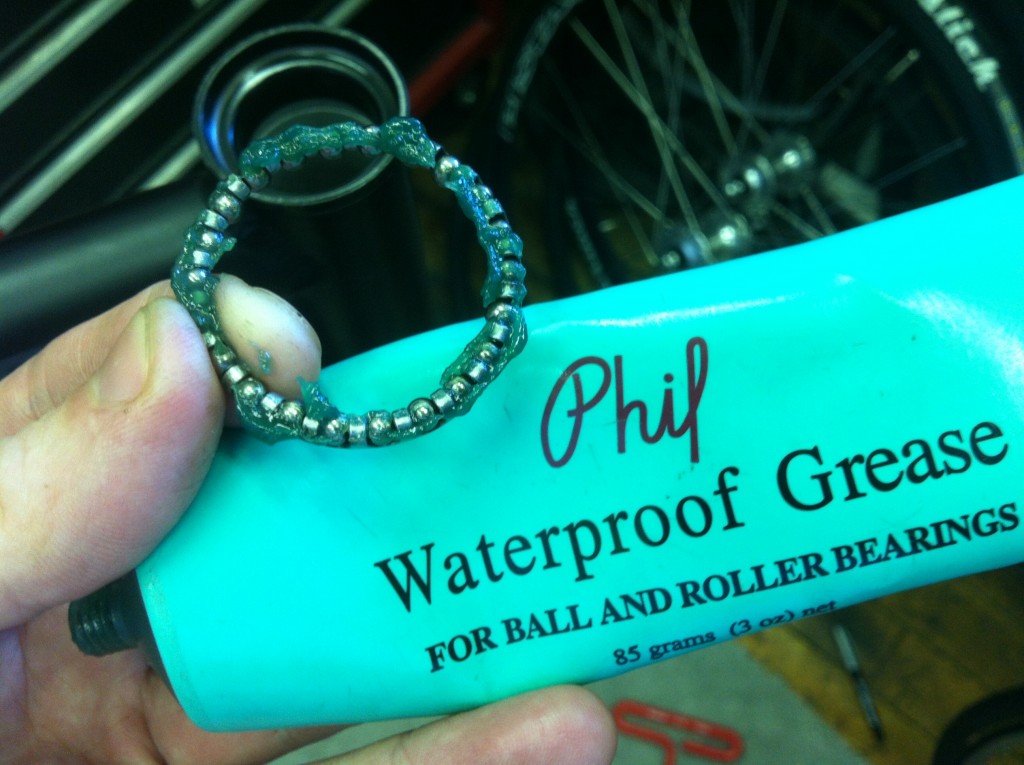

My headset bearings were pretty dirty and gummed up with debris, so it’s no wonder they weren’t turning smoothly. This headset uses caged ball bearings. They’re easy to clean, and difficult to lose. As you can see above, they came out looking pretty good. Some headsets have sealed cartridge bearings, some have loose ball bearings, but with any of these designs, grease is your friend:

Make sure you’ve cleaned the inside of the cups that are still in the frame, and the crown race which is at the base of the steerer tube. Apply grease generously and put each part back around the steerer tube in the same order:

Slide your (in this case new) stem on to the steerer tube, and push it down so it’s snug against the headset. The top of the stem should actually stick up above the top of the steerer tube by about 3-4mm. If it’s too short, add another spacer under the stem. Put the top cap back on, and thread the cap bolt back into the star nut. Make it snug, to compress the headset bearings, but don’t overtighten. If you do, it will be hard to turn the fork, and you’ll be putting extra wear on the bearings and cups.

Lastly, you need to secure the stem in place by clamping it to the steerer tube. These bolts are responsible for holding all of this together, so properly tightening them is extremely important. Check with your stem manufacturer for the recommended torque (it will probably be around 8 – 9N/m), and if possible, use a torque wrench to ensure they’re safely tightened.

With freshly cleaned and greased bearings, this fork turned effortlessly, a great improvement from it’s former state. My headset now feels nice and buttery 🙂

I have never seen such a short stem on a rigid fork. What sort of handlebars are you running?

It is technically a mtb stem. Running Cinelli riser bars with it.

I was noticing the fork. Was that an aftermarket addition? I wish the stock fork had eyelets for fenders! well at least the first years version didn’t have them.

Yea, that particular fork has never come stock on the Boston. A full coverage fender that bolted on would really stop you from folding the bike. We have quick release fenders like those on the Navigator and Boston 8 available. They’re not full coverage but they do a pretty good job, and are very convenient.

Hello everyone,

I need intel on my Mtb highline model headset specs!!

Anyone know where I can get this info??

Thanks 🙂

The stock headset is the FSA 10P. However, you could replace it with any zero stack headset made for a 1 1/8″ non-tapered steerer tubes. The inner diameter of the head tube is 44mm, outer diameter is 50mm.

Hi,we’re talking the direct connect 2016 frames right? I wanted to fit a conversion kit to run a tapered fork in my paratrooper pro 2015 model.. It seems the internal bore is too small.. I’m planning to get a 2016 bike or frame to build my perfect bike.. Can you give me any info on direct connect frame specs,full head tube details.. And where to buy in England or mainland Europe,thanks.. Daz.

That’s correct. The Highline is new for this year and those head tube dimensions are only for the DirectConnect frames. Head tube details are above: 44mm ID, 50mm OD, made for Zero Stack headsets.

We haven’t made DirectConnect framesets available separately at all, but complete bikes can be purchased from our UK or German distributor right now: https://www.montaguebikes.com/global-bike-distributors/

I got Montague Boston single speed bike. It has not got stem cap and a bolt. Also I lost the front brake bolt catcher which catches the front brake bolt from back of fork. What size measure I need for stem cap and bolt catcher please

Both parts are standard so you won’t need Montague specific replacements. The stem top cap is a universal size, for 1 1/8″ steerer tubes. You should find many options if you search “bicycle stem top cap”. Road style caliper brakes typically attach with either an external nut, or specially designed recessed brake nut. Our bikes use the recessed style, like this: https://www.google.com/shopping/product/75804023141106247

Hi. Can I install front fork from Paratrooper Highline to Navigator?

You could put the same fork on a Navigator if you bought it aftermarket. It would be compatible. It would change the geometry of the bike a bit since the suspension fork has a longer axle to crown than the stock rigid fork.

Hi, I’d like to replace the forks on my Crosstown with suspension forks (I accept that it would change the geometry of the bike a bit but my local roads are really lumpy). Could you give me the specs of the forks on the bike so I can find some compatible suspension ones please?

Any fork with a 1 1/8″ threadless steerer tube could be installed on your Crosstown, and of course you would want it to be made for a 700c wheel. If you’re planning to keep the Octagon system on there, you would probably want it to have a steel steerer tube. An aluminum steerer may have a thicker wall which would make the inner diameter smaller. In that case the vertical part of the Octagon may not fit down inside the steerer tube. If you’re planning to put on a standard stem, then any material is fine.

That’s great, thanks

Hi,

I’m going to replace my headset. What is the type/size do I need for a DX Crosstown?

Actually, it’s for DX Crossover.

The DX used a 1 1/8″ threaded headset

I recently bought a Paratrooper with a non threaded headset, not realising at the time that I can’t adjust the height of the handlebars. Can I change this by fitting a different type? It seems odd that in the larger frame sizes (for people over six feet tall) that it is not possible to adjust the handlebar height – it adds a lot of pressure on the wrists when the saddle is necessarily high up.

The handlebars can be raised with the addition of a steerer tube extender. It’s a very common part available from any bike shop. Most modern road and mountain bikes use a threadless headset and stem so your local shop can certainly help with raising them.

Hi, great article. I just bought a Boston frame (2016 closeout). What size crown race do I need?

That fork has a 1-1/8″ non-tapered threadless steerer tube and the frame accepts an external cup EC34 headset. Any EC34 headset should come with the correct crown race which would have a seat diameter 30.015 mm (sometimes specified as 30.1mm).

Hi. interesting build. I’m inspired to do a similar with either the closeout Boston or FIT frame. What size headset fits the older pre-2015 700c frames? Thx!

The included forks have a 1-1/8″ non-tapered threadless steerer tube and the frames accept an external cup EC34 headset.

I am planning to replace the original fork on my paratrooper. Just wondering if tapered fork can fit??

The head tube is made for 1-1/8″ straight steerer tubes so it does not have the diameter at the bottom for a tapered steerer. However, if your Paratrooper is 2016 or newer and uses an internal headset, you might be able to use an adapter headset lower made by Cane Creek, the 40-Series EC44-40 Bottom Assembly. This essentially moves the bearings into an external cup to allow for the wider fork at the bottom.

I have the Allston which just may be the best bike ever. I enjoy off-roading when available but need a suspension fork to ease the jolts of mountain terrain. What fork would you recommend that somewhat keeps the intended geometry?

Your new fork will of course need to be made for 700c wheels and will need a disc brake mount. A suspension fork with a relatively short travel would be best to retain similar geometry. The RockShox Paragon would be a very nice option for this (make sure it’s the disc version), but you could also find less expensive Suntour options.

I want to run a Chris King NoThreadSet on my old tried and true Paratrooper I just pulled out of retirement (purchased back around 2007). No particular reason. Replacing the shocks soon and I always thought the Chris Kind headsets just look pretty cool, so I figure it’s a great time to throw it on the bike. Any known compatibility issues? Thanks.

As long as it’s an EC34 headset (external cup, made for 34mm head tube), it should work just fine!

Did it. Looks great. This old 26er folding hardtail is still a great ride. Thanks.

Hi,

I have a 2011 Crosstown and the forks are loose, so I am guessing the headset bearings and Crown Race need replacing.

Am I correct in thinking a Threadless Headset, 1 1/8″ is the correct size and type of headset?

I can’t seem to find a replacement Crown Race.

Thanks

Tim

It has an Octogon handlebar/stem if that makes any difference to what is needed for the headset.

Yes, a 1 1/8″ threadless external cup headset is the correct size and type for the Crosstown from that era. They are also specified as EC34 headsets (External Cup, 34mm diameter head tube).

Hi, a nice write up on the headset overhaul. I own a later 2016 Boston using the direct connect CLIX system. When moving hse? I lost one of the crucial spares – Direct connect Clix system. Who can I get the direct connect CLIX system in Singapore ?

Hi Alex. We don’t currently have a distributor in Singapore, so you would likely need to source a replacement DirectConnect from Montague USA. Please send an email to info@montaguebikes.com to inquire.

Thanks. I just bought a second hand kids mtb for cheap. I knew it needed some maintenance but the more closely I looked the more it needed. My next job is the threadless headset overhaul so thanks for the comprehensive overview. This is the only instructable I could find that had the non cartridge type bearings which is exactly what I needed. Thanks

I have a recent (2016+) Paratrooper pro and want to change the fork for one with air suspension. I have seen several general online tutorials for this; however, when I remove the cap, handlebars and spacers, the fork does not simply come out as shown in them. There appears to be some sort of clamp-like ring holding it in place. Can you please tell me: 1) how to best remove this so that I can replace the fork, and 2) whether it needs to be put back on when I install the new fork? Thanks in advance!

Once the stem is removed, the fork would only be held in by friction, but they are often a bit difficult to get started. A few downward taps on the top of the steerer tube with a mallet should get the fork to start sliding down.